FEEDSCREWS AND HALF- NUTS

By Nipper

As briefly mentioned in Back to basics 3, feedscrews are found on most good quality Cylinder Phonographs, and also on some disc machines. Feedscews are basically threaded rods, which mathematically correspond to the grooves in the recording. When the reproducer is lowered onto the revolving cylinder the half-nut engages with the feedscrew, which is also revolving, it moves the carriage and reproducer across the record surface. Half -nuts, are literally half a threaded nut, although on some machines this is a knife-edge.

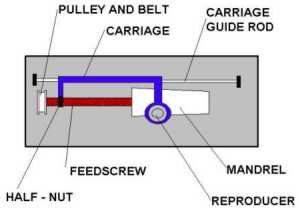

On the majority of cylinder machines the feedscrew is situated behind or in front of the mandrel and parallel to it. Feedscrews are generally driven off the mandrel via gears, which are designed to revolve the feedscrew at the correct speed to correspond to the type of cylinder being played, either 2 minute (100 grooves per inch) or 4 minute cylinders (200 grooves per inch) some machines have gearing for both types of cylinder, with a gear change mechanism. Other machines have the feedscrew as an extension of the mandrel shaft, as shown in the adjacent sketch; it also shows the general principal of how feedscrews work

For any cylinder machine to function correctly, the drive belt from the motor drive shaft pulley to the mandrel pulley, must not be too slack, causing the belt to slip, in this case the belt should be either shorted or replaced, also check the belt-tensioning device is operating correctly where fitted. The half-nut should also be correctly adjusted, this is achieved by an adjusting screw on most machines or by bending the half-nut arm, the half-nut should engage with the feedscrew with light pressure when in the 'engaged' position, so as not to cause to much drag, slowing the machine when the reproducer is lowered. The feedscrew should be kept very lightly oiled.

On the majority of cylinder machines the feedscrew is situated behind or in front of the mandrel and parallel to it. Feedscrews are generally driven off the mandrel via gears, which are designed to revolve the feedscrew at the correct speed to correspond to the type of cylinder being played, either 2 minute (100 grooves per inch) or 4 minute cylinders (200 grooves per inch) some machines have gearing for both types of cylinder, with a gear change mechanism. Other machines have the feedscrew as an extension of the mandrel shaft, as shown in the adjacent sketch; it also shows the general principal of how feedscrews work

For any cylinder machine to function correctly, the drive belt from the motor drive shaft pulley to the mandrel pulley, must not be too slack, causing the belt to slip, in this case the belt should be either shorted or replaced, also check the belt-tensioning device is operating correctly where fitted. The half-nut should also be correctly adjusted, this is achieved by an adjusting screw on most machines or by bending the half-nut arm, the half-nut should engage with the feedscrew with light pressure when in the 'engaged' position, so as not to cause to much drag, slowing the machine when the reproducer is lowered. The feedscrew should be kept very lightly oiled.